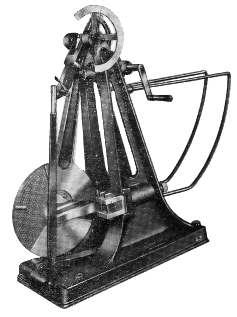

1921

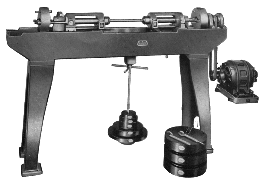

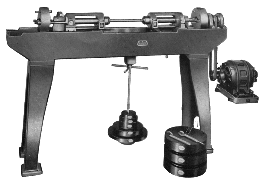

Ono Rotary Bending Fatigue testing machine

Development of the Ono-type rotating bending fatigue testing machine to perform four-point bending fatigue testing, where the specimen is supported at two points and loaded at two points.

This timeline highlights the evolution of Shimadzu's Material Testing products over the past 150 years. Each entry showcases Shimadzu's commitment to enhancing precision, efficiency, and user-friendliness in material analysis. From the launch of the first material testing machines to the latest innovations, Shimadzu has played a pivotal role in diverse industries, including construction, automotive, and aerospace, ensuring the integrity and safety of materials used in critical applications.

Development of the Ono-type rotating bending fatigue testing machine to perform four-point bending fatigue testing, where the specimen is supported at two points and loaded at two points.

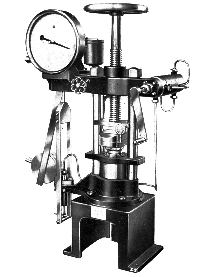

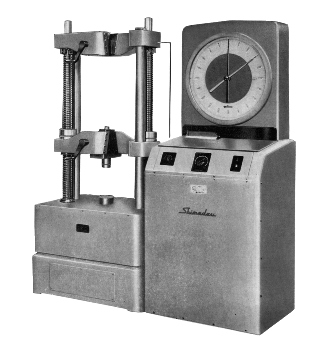

Start of manufacturing Brinell and Rockwell Hardness tester which were able to create an indention with the shape in accordance with the principle under certain loads.

Development of a customized Creep testing machine, which is capable on providing a constant 1T load over a long duration and recording the force and displacement.

Enabling of precise determination of Rubber hardness, which was not possible with hardness testing techniques for other materials.

Release of the first standard Shimadzu Charpy tester, capable of performing constant determination of impact toughness especially for metals.

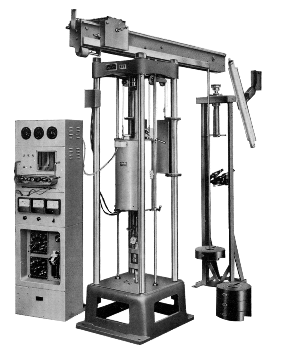

Development of a hydraulic universal testing machine enabling tensile, compression and bending test operated by a hydraulic power supply to ensure high forces accurately.

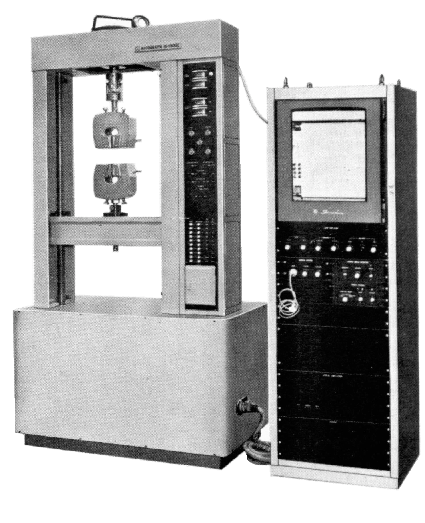

The first Shimadzu electromechanical testing system that records automatically the test-graph and by this visualize the connection of Force and displacement.

Structural Members need to withstand high forces and therefore need to be tested at high forces. This frame enabled testing up to 500T on big structural members.

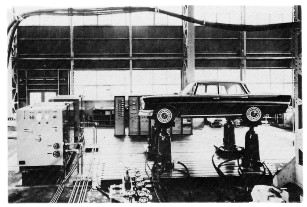

Manufacturing of Shimadzu first Fatigue testing system, named EVH. The System was dedicated for testing cars in their whole structure and is the first step in Shimadzu history of fatigue testing.

Delivery of the first Shimadzu fully automatic Charpy testing system enabling automatic Charpy tests.

Automation was already requested in early stages and Shimadzu followed the need by realizing a fully automated universal testing system for steel applications.

Proceeding in the way of improvement and standardization the AG-A universal testing system was released.

A foray in particle size measurement. The Sald 1000 was released enabling particle size distribution measurement from 0,1µm to 1000µm.

Further development in the Universal testing Serieas AG. Higher speeds, higher forces and better controlling lead to more accuracy in tensile, compression and bending tests.

The interest in creating compression test data for concrete material raised, therefore effort was put into a dedicated compression testing machine.

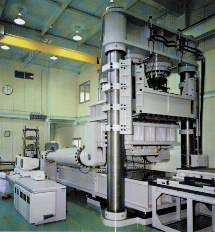

To prevent relevant data for seismic isolation Shimadzu realized a bixial fatigue testing machine, capable of earthquake simulation. By this safe infrastructure could be developed.

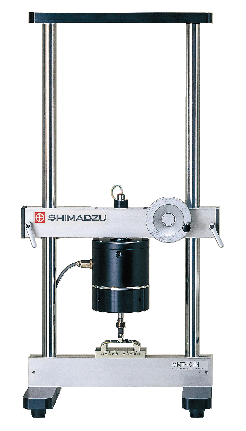

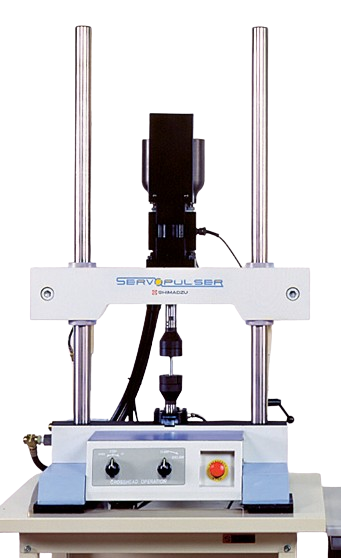

As not only big structures needed to be analyzed regarding their fatigue behaviour, the MMT Microservo was released. The small table top systems characterized by an electromagnetic actuator and frequencies up to 100Hz enabled fast evalution of fatigue behavior up to 500N. A step forward in dynamic testing.

As extrusion process besides other production processes developed more and more the anylize of flow testing got higher focus, leading to further development in the CFT500 Flow tester Series.

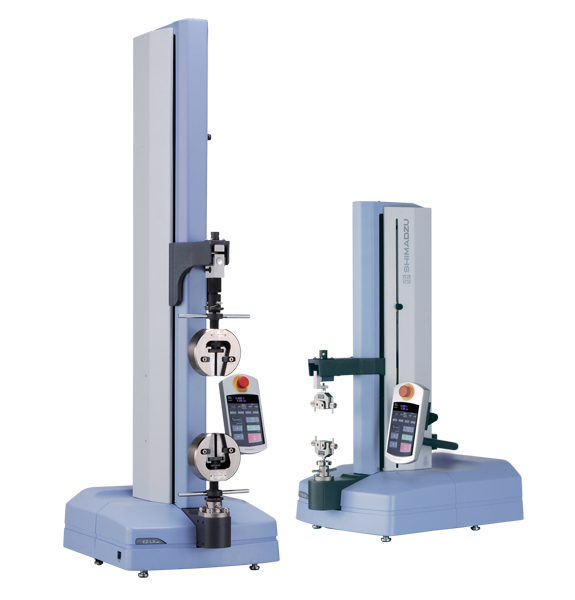

Putting more effort into footprint and laboratory size, the EZ-Test Compact table top tester was invented. Requiring just one column for small loads the need of installation place could be reduced, making it a perfect match for small loads application e.g. in Food and Pharma.

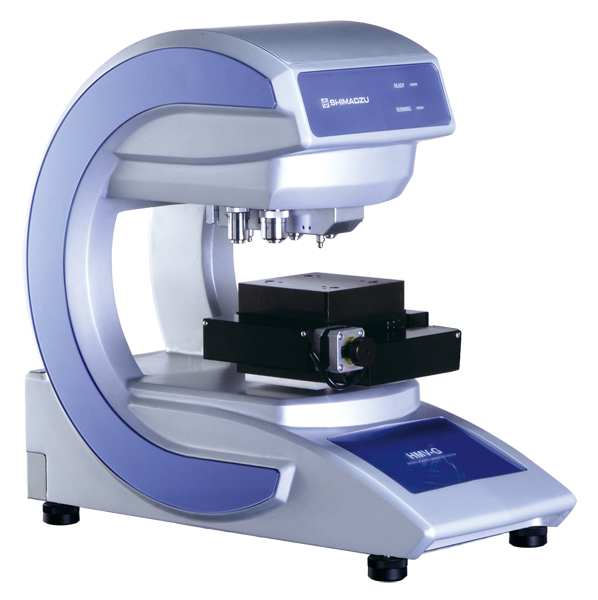

A further evolution step in hardness tester at Shimadzu, with the release of the HMV Series and the models HMV-1/2 enabling secure determination of Micro Vickers Hardness.

Putting dynamic tests at bigger loads on a table, the EHF-L System was invented. This small System allowed testing up to 20kN at 50Hz whilst being placed on a table.

As automatic successor of the CCM/CCH System for compression tests on concrete material the Concreto system was released to test concrete material upto 2000kN.

Development in speed and accuracy at small loads and small footprint. The EZ-Graph provides accurate measurements up to 10kN at speeds in the range of 0,0005mm/min up to 1000mm/min with a sampling rate of 1,25msec.

A milestone in terms of fatigue testing. The development of the Ultrasonic fatigue testing system USF 2000A enables enabled dramatique reduction of testing time using the resonance frequency of the specimen at 20kHz.

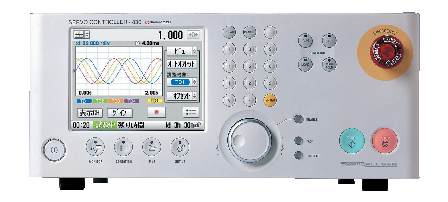

Dynamic testing requires accurate controlling. One part of the story is the frame providing the movement and holder the specimen, the other part is the controller, giving commands, reading results and eliminating movement errors leading to a highly accurate movement control and measurement results. The 4830 combines all of this.

Further development in the state-of-the-art Series for universal testing the AG-X incorporates a high accuracy, high speed, high forces and a perfect control building a state-of-the-art system.

Everything becomes faster, therefore we need to be able to observe things faster. The HPV-2 Camera enables observing high speed phenomena at 1million frames per second. Revealing the unseen.

Not just R&D require accurate results, also the demand for accurate measurements in Q&A is required. With the AGS-X the system for Q&A was renewed. High Speed testing and sampling, allows fast and reliable results for production lines.

The request for clean labs and clean systems, questions the need of oil as source to realize dynamic tests. Were high forces are not required, electrodynamic systems are the answer. The EMT allows tests up to 1kN with frequencies of 200Hz whilst completely electric driven. Green transformation in early stages.

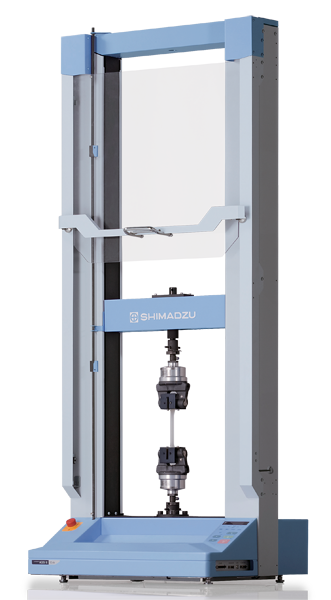

Where electromechanics reach their limits in terms of force/place ratio, hydraulic power is the answer. The UH_X/FX Series is the successor of the long history of hydraulic testing systems and enables state of the art testing at high forces up to 4mN.

The need of texture analyzes pushes the need for small test systems fitting into food and pharma laboratories. The EZ-X is the continuation of the success of the EZ-Graph System, providing high accuracy, speed and control at loads up to 5kN whilst having a small footprint.

A unique technique taken a step further. The HPV-X allows recordings of up to 10 million images per second, enabling high-speed phenomena to be viewed on a different level.

Hardness testing remains an important testing technique for materials, and Shimadzu continues the history in this application field, providing a successor of the HMV 1 / 2 with more load stages, multiple indenters and multiple lenses to be attached at the same time.

The CFT calculates shear rate, melt viscosity, and flow beginning temperature by applying heat and test force to resins in pellet form or other form and extruding it from a capillary tube. A technique that’s being used by Shimadzu already for years, perfectly aligned for the actual processes.

As light matters – even more at such recording speeds – the FTCMOS Sensor used in the HPV-X was exchanged by the newly developed FTCMOS 2 image sensor leading to a six times higher sensitivity and high improvement of the image quality.

The determination of viscosimetry, can be different from material to material and the required characteristic values. The SMV301 enables accurate measurement Mooney viscosity and Scorch time of unvulcanized rubber.

The USF 2000A was already a milestone in fatigue testing but enabled just testing without applied meanstress and a stress ration of R=-1. With the integration of the technique in the Autograph testing frame, testing with a meanstress of 1,5kN become possible – opening new opportunities.

Single dynamic actuators are still mostly driven by hydraulic power. As the trend and requirement is going into clean energy, the electomechanical actuator NJ Servo was invented to realize fatigued test completely electrical driven up to a load of 30kN.

Faster Speeds, higher accuracy range, more applicable sensors are just some of the benefits that are included with the new AGX-V system – the successor of the AG-Xplus System for Universal testing in Research and development. The AGX-V incorporates the knowledge gathered over 100 years of testing and meets the highest standards!

Hardness testing is indispensable in the research of metallographic structures. The renevel of the HMV-G20 allows being compliant with the most actual standards and enabling precise automatic measurement.

As a driver for innovation and with a long experience in material testing, a complete new evaluation technique is invented. By the combination of sheraography with ultrasonic vibration the ultrasonic optical flaw detector is born. This enables visualization of defects like, Cracks, voids and delamination below the surface.

The extension of the AGX-V Product line by wide type, reinforced yoke and separate controller type models complete the portfolio and enlarge the field of applications that can be covered. In addition, the user interface is gets a never been seen feature - XV-Talk enables voice control of our testing system!

Throughout its 150-year history, Shimadzu has gathered numerous stories that exemplify its role in the advancement of analytical technology. Each narrative reflects the contributions of individuals and the evolution of innovations across various fields. Below, we present some of these stories that highlight key milestones in our journey and the impact they have had.

Today, societies require an intelligent infrastructure capable of detecting threats and equipped with early warning systems. Though built to last, collapsing buildings and infrastructure is a common occurrence throughout the world. Diagnosing civil engineering and geotechnical facilities is therefore absolutely mandatory in order to avoid damage and save human lives. One of the most promising approaches is the use of monolithic fiber optic sensors that are fully integrated into a given structure, providing strain, displacement, temperature or vibration monitoring continuously over its entire length – from millimeter to kilometer range!

Despite the intense development of the biomaterials sector, wound management is a great challenge worldwide, laying a huge financial burden in all countries. One of the significant challenges that medicine has to face up until the 21st century is that conventional wound dressings facilitate the wound healing but not as efficiently as expected. Smart hydrogel wound dressings, such as stimuli-responsive and self-healing materials, may help to solve this problem. The development of a dressing prototype with antimicrobial potential that is able to respond to changes in the pH of the environment and is flexible and time-efficient when changing may be a great milestone in this field.

Rimac Technology designs and manufactures high-end electric hypercar components. Based in Zagreb, Croatia, the company is part of the Rimac Group, which also includes Bugatti Rimac, and has a well-established reputation for the engineering, development and production of high-performance battery systems, electric drive units, electronic systems and user interface components. As part of Rimac’s drive to refine its competitive edge in this exceptionally demanding field, the company recently acquired advanced Shimadzu material-testing machines. Two company experts tell us why.

An electric power grid is a socially and economically critical installation and its components must meet exacting performance and safety criteria. The Central Mining Institute (GIG) in Poland tests and verifies the mechanical properties of overhead conductor wires for compliance to current standards. Using Shimadzu equipment, GIG is able to minimize human error in testing via an automated process. The result is a reliable, simplified method.

Are you interested in our Material Testing products? You can explore them up close at various upcoming events. Our experts will be available to answer any questions you may have. We look forward to seeing you there!

Shimadzu provides a comprehensive range of material testing solutions designed to meet the diverse needs of our customers across various industries. Our portfolio includes advanced testing machines such as Universal Testing Machines (UTM), hardness testers, and dynamic mechanical analyzers, all engineered to deliver precise and reliable results. We also offer a variety of accessories and specialized fixtures to enhance testing capabilities and ensure optimal performance.

With user-friendly software and high-quality consumables, Shimadzu is dedicated to delivering innovative material testing solutions that empower researchers and manufacturers to achieve accurate and consistent results.

The AGX-V2 Series Universal Testing Machine represents the pinnacle of Shimadzu's material testing technology. With its remarkable precision and reliability, this next-generation machine is designed for a wide range of applications, from tensile and compression testing to flexural and shear tests. Its intuitive software and advanced features streamline the testing process, making it easier than ever for users to obtain critical data.

Shimadzu's Universal Testing Machines (UTM) deliver precision and reliability for diverse material testing applications, including tensile, compression, flexural, and shear testing. Engineered with advanced technology, they ensure accurate measurement of mechanical properties for effective material performance assessment.

Since 1967, Shimadzu has developed a comprehensive range of fatigue and impact testing systems, including the EVH Fatigue Testing System for automotive applications, to evaluate material durability and toughness under various stress conditions. Our machines conduct cyclic loading tests to determine fatigue limits and life expectancy, while impact testing systems measure resistance to sudden impacts, providing crucial data on toughness and resilience.

Since introducing the Brinell hardness tester in 1931, Shimadzu has developed advanced hardness testing systems that meet modern manufacturing and research needs. Our versatile solutions use established methods like Rockwell, Brinell, Vickers, and Knoop, providing consistent results across various materials while simplifying the testing process with user-friendly interfaces and intuitive software.