GCMS-QP2020 NX - Features

Gas Chromatograph Mass Spectrometer

Smart Performance

Provides higher sensitivity and reduces operational costs

A large-capacity differential exhaust turbomolecular pump and a high-performance flow controller ensure that the utmost in sensitivity is obtained under all conditions used for GC. This sensitivity combined with high-speed analysis capabilities helps maximize laboratory efficiency by reducing analysis times. In addition, the system can be safely operated using carrier gases other than helium, such as hydrogen or nitrogen, thereby reducing operating costs.

Technology Achieves High Sensitivity

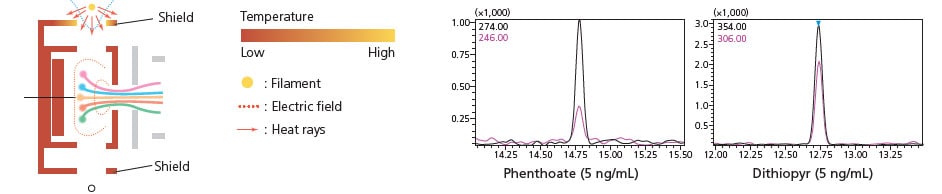

Ion Source Featuring High Sensitivity and Long-Term Stability

The filament and the ion source box have been separated, which reduces the impact of the filament potential on the interior of the ion source. In addition, a shield is provided to block radiant heat generated by the filament, achieving a uniform temperature inside the ion source box. Thus, active spots inside the ion source are not prone to occur, enabling high-sensitivity analysis with long-term stability. (Patent: US7939810)

New Flow Controller Achieves Exceptional Reproducibility

A new flow controller (AFC) with a CPU uses various control methods to control carrier gas flow to a constant flow speed, flowrate, or pressure. It can also accurately trace the analytical conditions already being used. The split line filter can be replaced without any tools. Internal contamination can be confirmed visually, ensuring filters are replaced at the proper time.

Large-Capacity Differential Exhaust System

Through adoption of a new type of turbomolecular pump with increased exhaust efficiency, the system's performance is greatly improved when using hydrogen or nitrogen, in addition to helium, as the carrier gas. Moreover, a differential exhaust method is used to create a vacuum separately for the ion source and the quadrupole. As a result, an optimal MS state can be realized regardless of the conditions imposed by the carrier gas used.

ClickTek Nut

One Touch Inlet Maintenance

The injection port can be opened or closed without tools by simply sliding the ClickTek™ lever. Replace the insert, slide the lever and feel the click for a leak-free install every time.

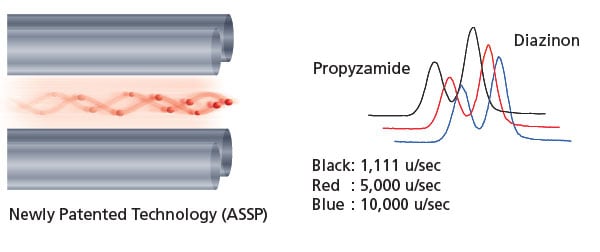

High-Speed Scan Control Technology

Advanced Scanning Speed Protocol (ASSP™)

The rod bias voltage is automatically optimized during high-speed data acquisition, which minimizes sensitivity deterioration during high-speed scans of 10,000 u/sec or faster. The sensitivity obtained is at least five times better than with conventional systems. This is effective for scan data sensitivity improvements and favorable mass spectrum acquisition, particularly in high-speed analysis with Fast-GC/MS, simultaneous Scan/SIM, FASST analysis, and applications using GC × GC-MS. (Patent: US6610979)

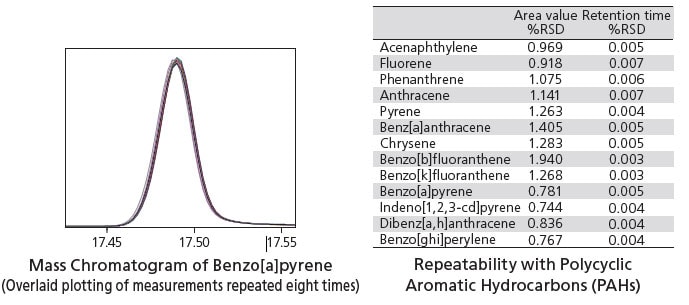

Advanced GC Oven

The improved temperature control function enables more precise temperature control of the GC oven, which improves the precision of retention time reproducibility. In addition, three oven cooling rate levels can be specified to minimize damage to column liquid phases and maximize the service life.

Reduced Operating Costs Using Alternative Carrier Gases

Hydrogen and nitrogen are less expensive than helium and are readily available, so they are attracting attention as alternative carrier gases. The high-performance Advanced Flow Controller (AFC) provides accurate control even with hydrogen and nitrogen. In addition, the new large-capacity differential exhaust system enhances the vacuum performance when hydrogen or nitrogen is used as the carrier gas, so the optimal MS state is achieved under all carrier gas conditions.

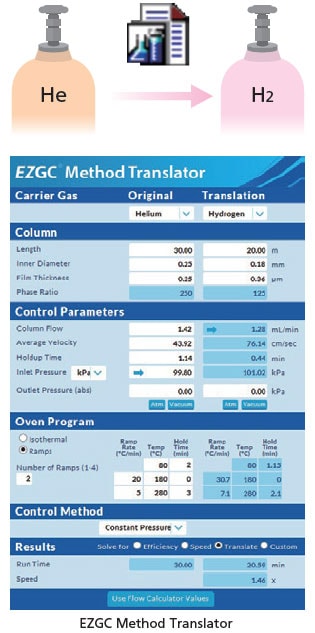

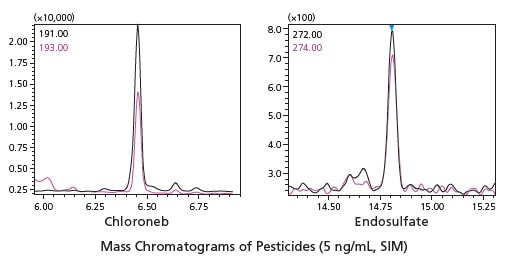

Application Example Using Hydrogen as the Carrier Gas

Hydrogen and nitrogen provide less sensitivity than helium. However, chromatogram patterns equivalent to when helium is used can be obtained by using a short column with a narrow internal diameter. EZGC® Method Translator*1, a method conversion program provided by Restek, can convert the analysis conditions when helium is used to the optimal analysis conditions for the alternative carrier gas.

*1 EZGC is a trademark of Restek Corporation.

For details, refer to the Restek Corporation website.

http://www.restek.com/ezgc-mtfc

The retention indices are essentially unchanged even when the conventionally used analysis conditions are converted for using hydrogen as the carrier gas.

Mass spectral libraries containing retention indices and databases provided by Shimadzu should be used.

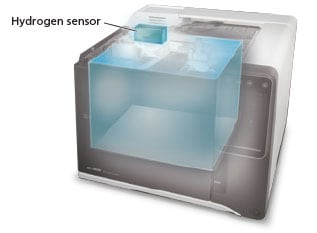

Hydrogen Sensor Monitors Inside of GC Oven

Hydrogen Sensor Assures Safety

A hydrogen sensor (optional) can be installed inside the GC. By discovering potential leaks in advance, accidents can be prevented. Furthermore, the main unit is equipped with an automatic carrier gas leak checking function, which strongly supports the use of hydrogen as a carrier gas.

Smart Operation

Dramatic improvement in the efficiency of multicomponent simultaneous analysis

The efficiency of multi-component simultaneous analysis is dramatically improved thanks to Smart SIM™, which simplifies and automates the method creation, and LabSolutions Insight™ software, which greatly reduces the time needed for analyzing data. In addition, databases specialized for specific fields are provided, so regardless of the field in which quantitative analysis is to be performed, highly reliable data can be obtained as the result of the optimized analytical conditions.

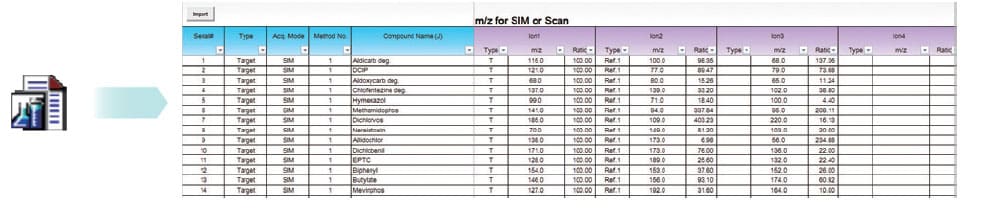

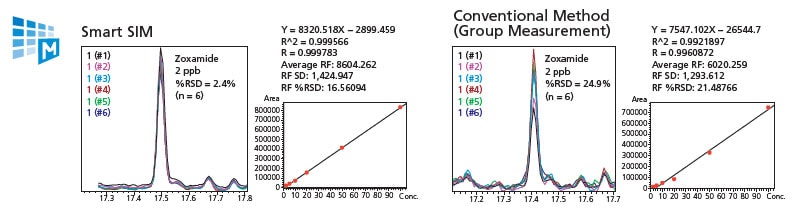

More Convenient Multicomponent Analysis Achieved by Smart SIM

The Smart SIM automatic method creation function automatically configures the SIM program to suit the retention times.

Even in cases where there are a number of compounds and they are apportioned to multiple methods, the methods can be integrated while maintaining the sensitivity as is. This significantly reduces the number of analysis cycles and the measurement time, improving productivity.

All compound information contained in methods for currently used Shimadzu GC/MS systems can be stored in the database simply by selecting the files.

High-sensitivity, high-accuracy analysis is enabled in comparison to the group measurement method. In a batch analysis of 434 components, favorable repeatability and calibration curves were obtained, even down to the trace-quantity region, improving quantitative performance.

LabSolutions Insight

LabSolutions Insight has been designed to drastically simplify the review process and transform data processing.

Smart Data Management

Easily obtains all the information required for qualitative analysis

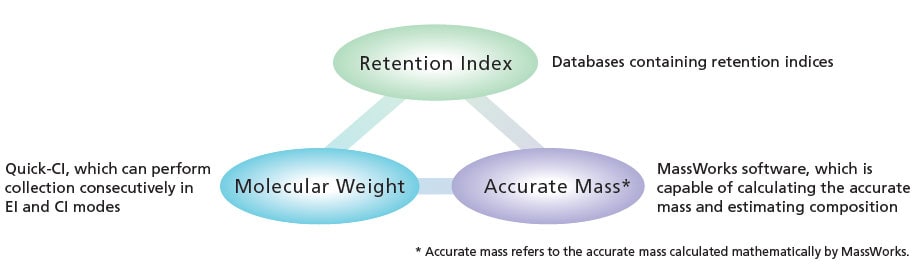

With GC/MS, which has significant qualitative capabilities, a wealth of fragment information is obtained, so it is used as a means of identifying unknown compounds. A mass spectral library is generally used as a means of compound identification. However, experience with compound identification is required if the compound is not registered in the mass spectral library, or there are a number of compounds with similar structures. With the GCMS-QP2020 NX, in addition to the mass spectrum, three kinds of value-added compound information are used in combination to support high-accuracy qualitative analysis.

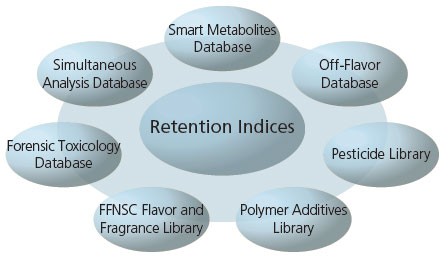

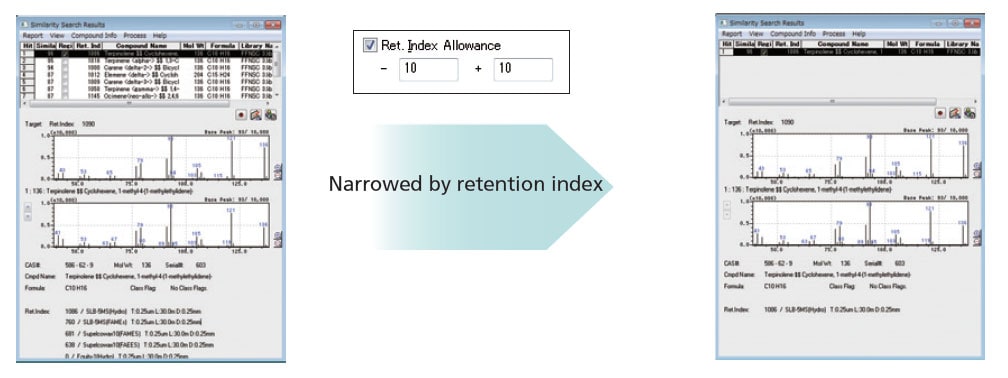

Databases Containing High Value-Added Retention Indices

Databases are available with retention indices specific to a variety of application fields, including foods, chemistry, fragrances, forensics, and metabolite component analysis. In addition to mass spectra, searches are performed in combination with retention indices, which are very highly compound specific, so isomers and compounds with similar structures are accurately identified.

Other Mass Spectra Libraries

• NIST Mass Spectral Library

Registered with approx. 350,643 spectra.

• WILEY Mass Spectral Library

Registered with approx. 775,500 spectra.

• GC/MS MPW DRUG Library

Drugs, toxicants, pesticides, environmental pollutants

(approx. 10,430 compounds)

Up to 10 library files can be configured. In addition to the public NIST and Wiley libraries, a variety of library files can be configured. In addition, there is a function to easily create private libraries.

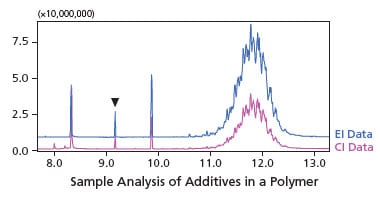

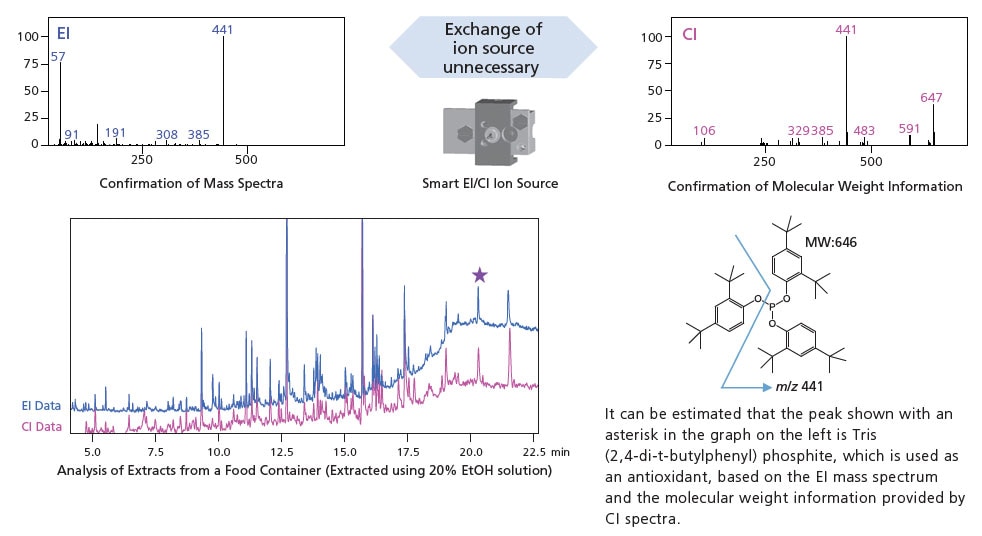

Smart EI/CI Ion Source Easily Switches Between EI and CI Methods

The Smart EI/CI ion source has been developed in order to acquire CI data without switching the ion source, and without losing the sensitivity of EI, which is most commonly used. Even when it is difficult to perform identification with the EI mode using the mass spectral library, molecular weight information can be obtained from CI data, thus helping in the estimation of unknown compounds.

Estimating Composition Using Accurate Mass

The MassWorks software calculates the theoretical accurate mass from the quadrupole MS mass profile. It then outputs candidate compositional formulas based on isotopic ratios and the theoretical accurate mass. This software is useful for estimating the composition of compounds that are not registered in a mass spectral library. The GCMSsolution™ software can simultaneously output GC/MS data and mass profile data. The majority of compounds detected with the GC/MS data can be identified from a mass spectral library. MassWorks is then used to estimate the composition of any compounds that are not identified, further increasing the quality of the qualitative analysis.