Mechanical Strength Evaluation of Functional Film Used in Smartphones

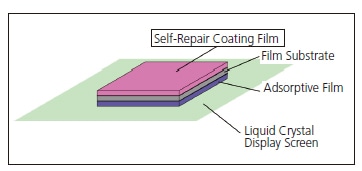

Recently, a wide range of multi-functional films have been developed which possess a variety of special characteristics designed to provide such functionality as enhanced protection and visibility in display screens for smartphones and LCD televisions. These multi-functional plastic films can also be designed to provide enhanced security, insulation, and light shielding for automotive and architectural glass products. This page introduces an example of the strength evaluation of self-repair coating film used on the functional protective film that covers the LCD screens of such products as smartphones and tablets.

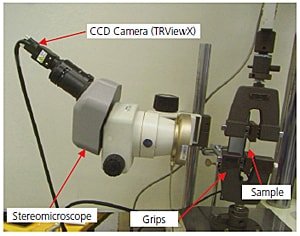

Fig. 1 Test Apparatus

Fig. 2 Sample Structure

Table 1 Test Conditions

| Instrument | Micro Autograph MST-1 |

| Test Force Measurement | 1 kN load cell |

| Test Speed | 5 mm/min |

| Grips | 1 kN screw type flat grips |

| Grip Teeth | File teeth |

| Video Observation | TRViewX Non-Contact Digital Video |

| Stereomicroscope | |

| Software | TRAPEZIUM X (Single) |

Table 2 Sample

| Sample (dimensions) | Width 10 mm, length 40 mm (strip shape), thickness 150 μm |

| PET self-repair film |

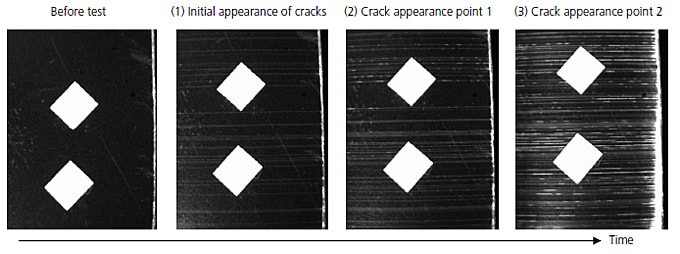

Fig. 3 shows the time-course changes in the self-repair coating film at the sample surface that were extracted from the TRViewX tensile test video. Here, the characteristic changes that occurred in the sample at various states during tensile loading are displayed in photographs. The captured states include: (1) Initial appearance of cracks: the point at which localized minute cracks first appear in self-repair coating film, (2) Crack appearance point 1: the point at which the c racks become c lear l y ev ident , and (3) Crac k appearance point 2: the point at which the cracks become evident over the entire coating film, imparting a whitening effect.

Fig. 3 State of Self-Repair Coating on Sample

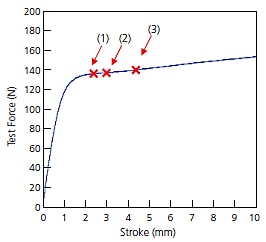

Next, using the TRViewX Point Pick feature, we quantified the test force loaded onto the sample and the amount of deformation that occurred at states (1), (2), and (3) of the self-repair coating film. Fig. 4 shows the Test Force -Stroke curve.

Table 3 Test Results

| Test Force (N) | Stroke (mm) | |

| (1) | 135.66 | 2.38 |

| (2) | 137.25 | 2.98 |

| (3) | 139.53 | 4.36 |

Fig. 4 Test Force - Stroke Curve

Fig. 4 reveals that the cracks occur in the self-repair coating film after the sample exhibits non-linear behavior - that is, when the plastic region has been reached. It is therefore presumed that the self-repair coating film possesses strength properties that prevent its damage in the elastic region. The cracks in the coating film appeared at about the 135 N load point, and after the cracks became clearly evident at a load point of about 137 N, the cracking suddenly became very pronounced over the range of 137 N-140 N.

Micro Autograph MST-I

Micro Strain Tester

In recent years, devices and components have become increasingly downsized and are being mounted at higher densities due to the trend towards thinner, lighter and smaller electronic devices equipment. Accompanying this, in the field of strength evaluation testing, there has been an increasing need for testing machines that can control and measure displacement and test forces on micro samples in the several µm or several mN micro regions and that can evaluate strength to high precision. The Shimadzu Micro Autograph MST-I has been developed and put onto the market in response to this need for a micro strength evaluation testing machine primarily in the electronic components sector.

TRViewX

Non-Contact Digital Video Extensometer

Elongation and width are measured by video camera. JIS B7741 class 0.5 elongation, and JIS class 1 width can be measured in a non-contact manner to high precision. Tests using a thermostatic chamber also can be accommodated.